Custom GRC Options & Extras

Satu Bumi has a whole range of custom finishes, textures, designs, sealants and drainage options for its Wholesale and CityScape Ranges of GRC planters that will enable Satu Bumi customers to align the functionality and/or aesthetic appearance of their GRC planters to the requirements of virtually any specific landscaping project or GRC planter marketing initiative.

However, not all the options shown below are available for every Satu Bumi product for a variety of both commercial and practical reasons. Therefore, although it is a good idea to understand the variety and flexibility of what can be done with GRC, it will also be important to discuss your thoughts on option selection with a Satu Bumi representative prior to finalising your requirements.

GRC Finishing Options

Standard Colour Options

GRC products can be ordered in any of Satu Bumi’s following standard colours at no additional cost:

-

This is a natural raw concrete look made with grey cement without the introduction of any additional colouring.

-

This is also a natural raw concrete look. However, it is made by replacing the grey cement with white cement and also without the introduction of any additional colouring.

-

This is one of our most popular colour options and is made by applying a specific dosage of an integrated oxide colouring additive to either the natural grey or the natural white GRC mixes during the manufacturing process.

Natural Grey GRC Finish

Natural White GRC Finish

GRC Charcoal Finish

Aggregate Finishes

GRC products can be ordered with several standard Satu Bumi aggregate finishes that can be viewed by clicking the image to the right. However, if you require alternative aggregate finishes, contact Satu Bumi to discuss what this means.

Additional Integrated Colour Options

In addition to the above standard colours and aggregate finishes, you can also choose any colour from a whole range of integrated colour options off the CCS colour chart. These colours are achieved by adding oxide pigments to the GRC slurry prior to it being added to precast moulds in the production process. The additional cost of these optional integrated colours varies depending on the colours chosen and their pricing can be provided upon request. The advantages of integrated colouring options are that they don’t change the natural concrete appearance of GRC, and superficial damage doesn’t expose a different colour substratum.

The images below are a limited number of examples of a planter with different integrated pigment colours to show the types of colour variations that can be achieved.

Due to the varying cost of the ingredients that go into the pigmented colours, the prices of the different coloured pigments also vary quite considerably. The picture to the right shows an example of a Satu Bumi installation that utilise various GRC planter shapes and sizes in conjunction with a selection of subtly different integrated pigment colours to achieve a soft and appealing ambience.

Oxide Surface Finish Options

Oxide surface finishes provide earthy and industrial appearances that cannot be achieved by integrated colouring and painted finishes. These finishes are applied to the GRC surface and Satu Bumi provides the following five standard options that add around 5% to the price of the GRC product being treated:

Rust provides the industrial light-coloured appearance of heavily rusted steel.

Iron Ore provides the earthy appearance of dark and rich iron ore.

Iron Stone provides the earthy appearance of a light-coloured ancient stone.

Cast Iron provides the industrial dark-coloured appearance of weathered cast iron.

Neo Coffee provides the rich, warm appearance of dark roasted coffee with smooth, polished surfaces and subtle depth.

Verdigris provides the appearance of rusted copper.

Rust Finish

Iron Ore Finish

Iron Stone Finish

Cast Iron Finish

Neo Coffee Finish

Verdigris Finish

GRC Texture & Finish Options

The versatility of GRC enables the application of different surface texture and finish options such as brushed surfaces, pitted surfaces, colour inlays and moulded designs such as faux wood.

Agregate Surface Finish

Weathered Surface Finish

Brushed Surface Finish

Pitted Surface Finish

Coloured Inlay Finish

Salvaged Surface Finish

Moulded Timber Finish

Glow In The Dark Finish

Examples of a GRC planters and benches installation with a customised brick-looking textured finish

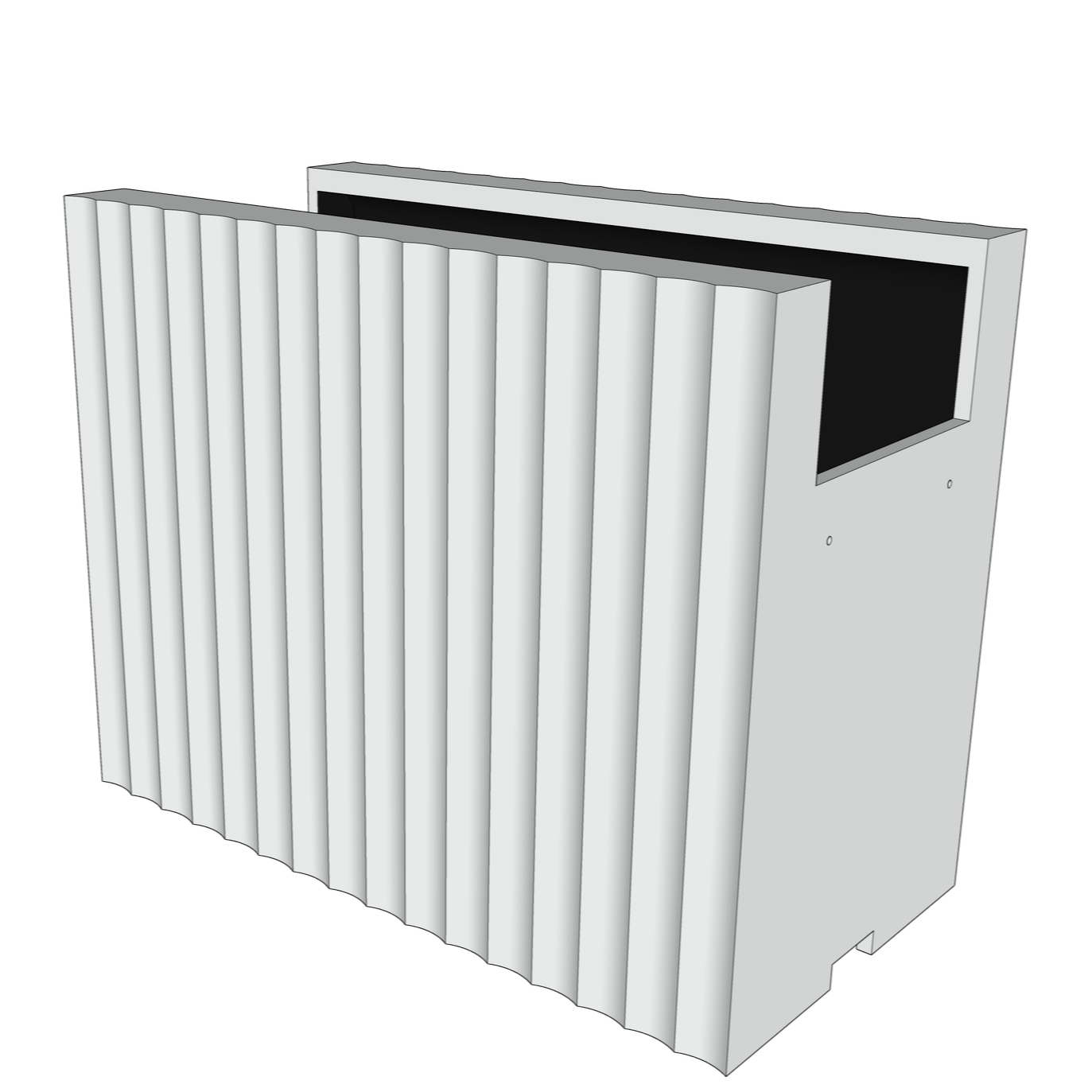

Specialty Paint Finish Options

Today’s acrylic paint technology enables the painting of concrete surfaces to almost any colour. Unless otherwise defined by the customer, Satu Bumi uses Dulux Weathershield paint in Low Sheen, Semi-Gloss or Gloss finish for its specialty painted finishes. The prices of the painted finishes are approximately 9% of the prices of the planters to which the paint is to be applied and the colours can be selected with reference to the official Dulux web site.

Paint is a surface coating that provides a more consistent and solid colouring outcome than what can be achieved using integrated pigments in the concrete mix. However, the use of integrated pigment colouring provides a more traditional coloured concrete appearance than has its own appeal.

Either colouring method will provide a good result. Therefore, the decision on which to use is generally a matter of design intent.

Example of a painted GRC planter - with a drop down righthand side wall, a bottom inset, and a corrugated texture front finish

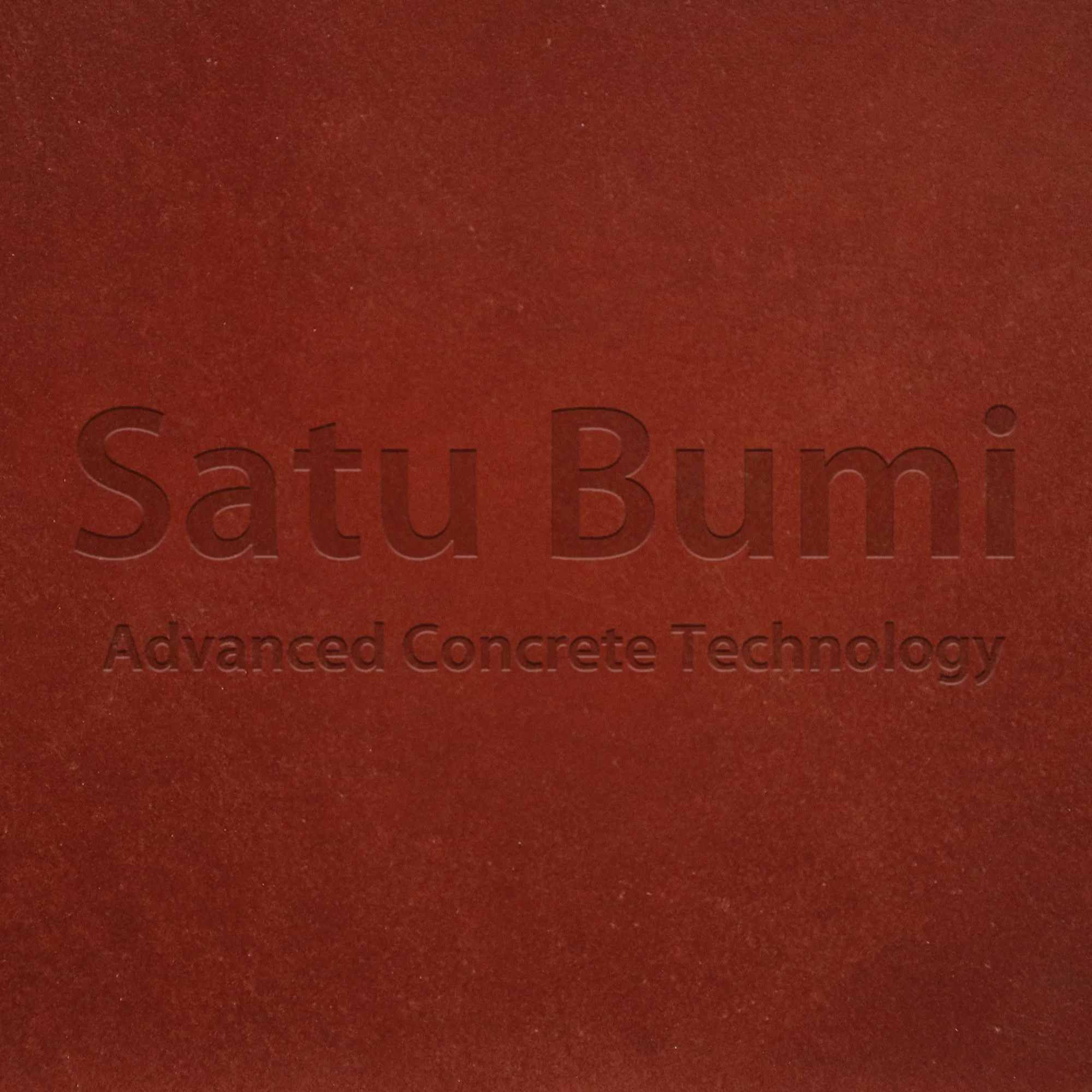

GRC Swatches

It is important to note that screen-based swatches and colour samples are provided for explanatory reasons. Computer screens should not be solely relied on for colour decision making because they can vary based on the screen (make, model and type), screen settings (resolution, contrast and control) and room lighting (incandescent, fluorescent, halogne or natural light). Therefore, where appropriate, Satu Bumi will supply swatch samples to address this issue.

Satu Bumi swatches for the cityscape range

GRC Design Options

With a large product engineering department of designers and mould makers, Satu Bumi is able to provide a wide range of product design options to suite the most discerning architects and designers. The following are examples of some of the design options that can be considered for GRC products.

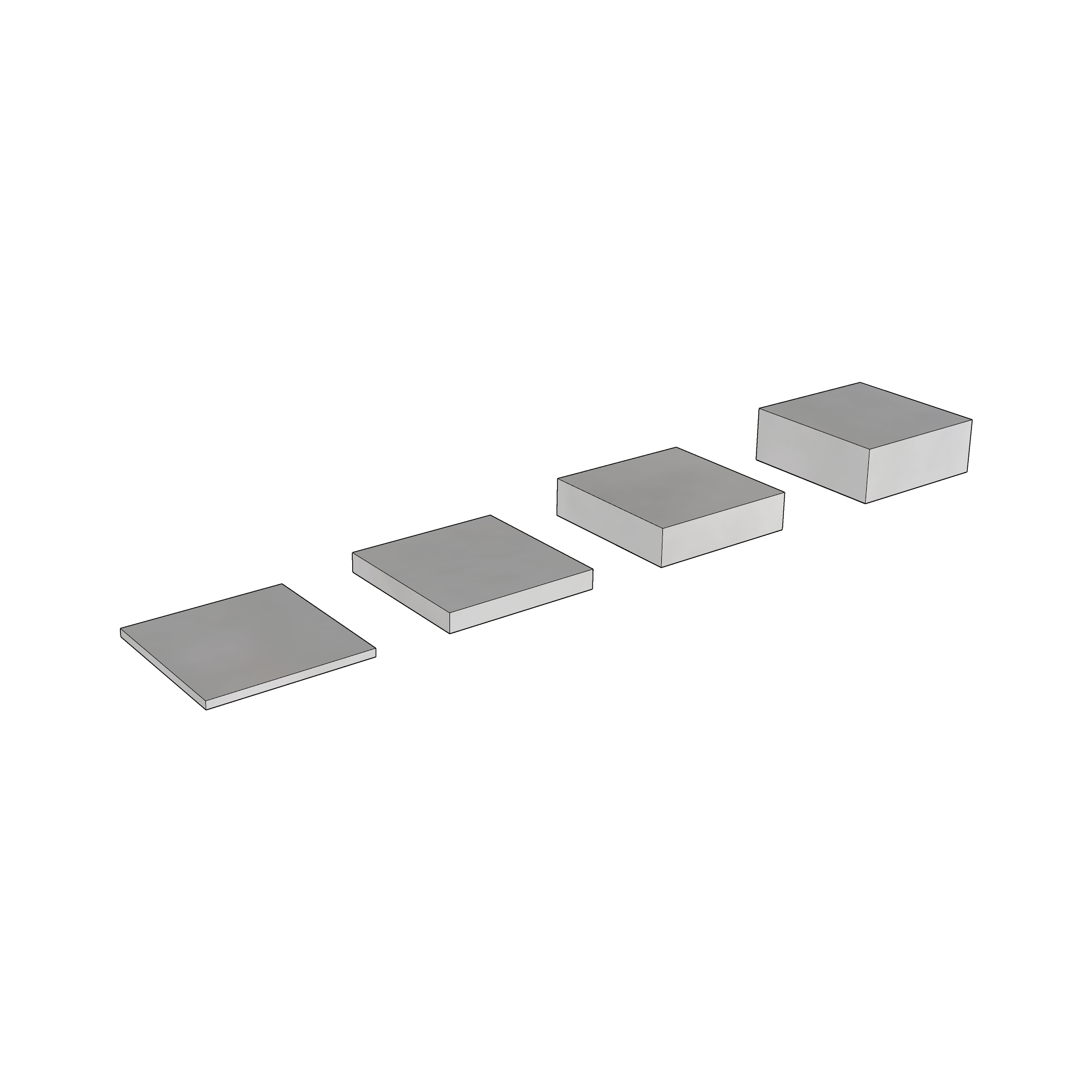

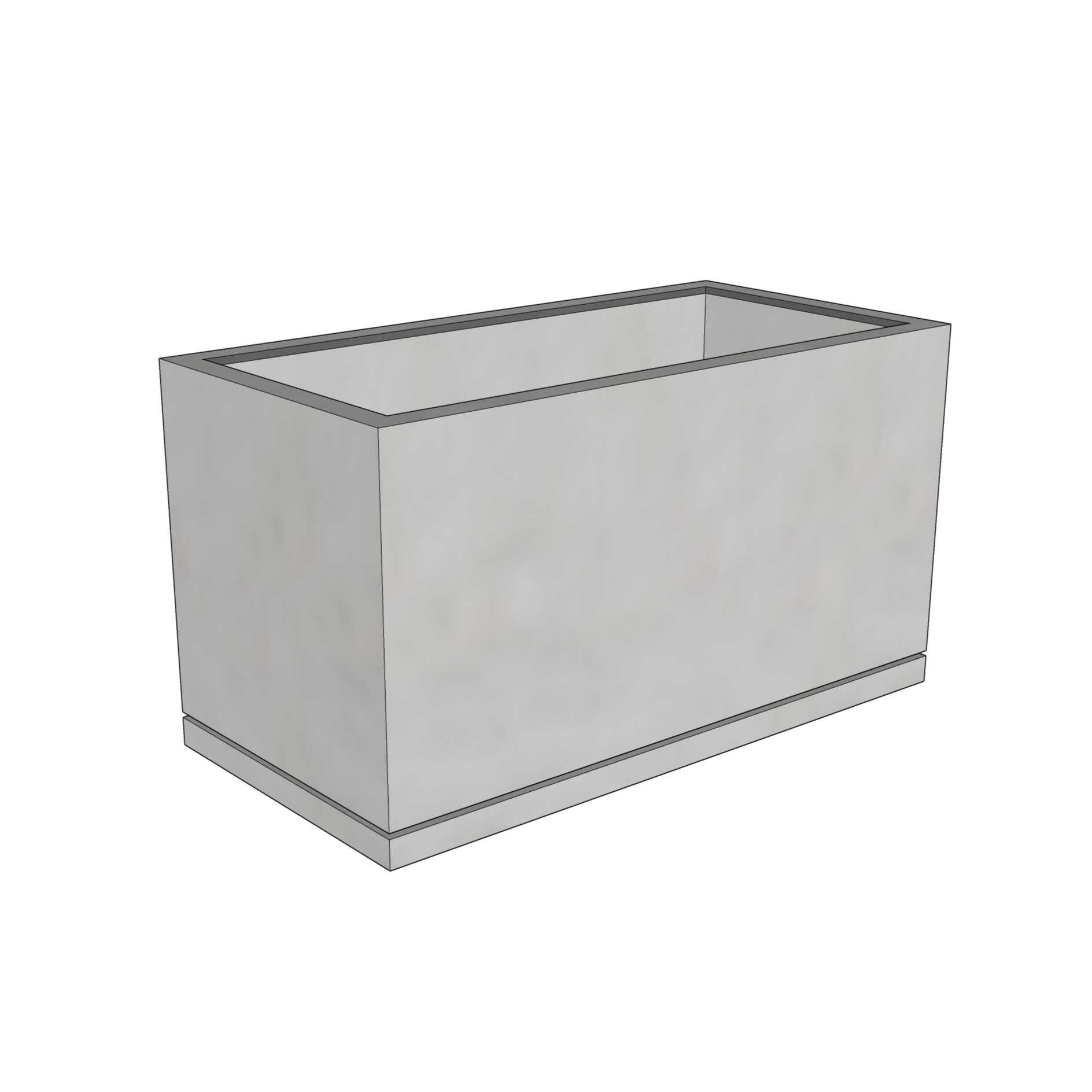

Standard Planter Feet Options

Planters are typically supplied with feet of around 2 cm high. However, the planter feet height can be easily varied upon request. This can be useful in circumstances such as when a planter is going to be installed with pods and pavers, and you want to raise the bottom of the planter to the level of the pavers.

Planter Bottom - Strip Feet

Standard Feet Design

Optional Feet Heights

Feet Heights - Side View

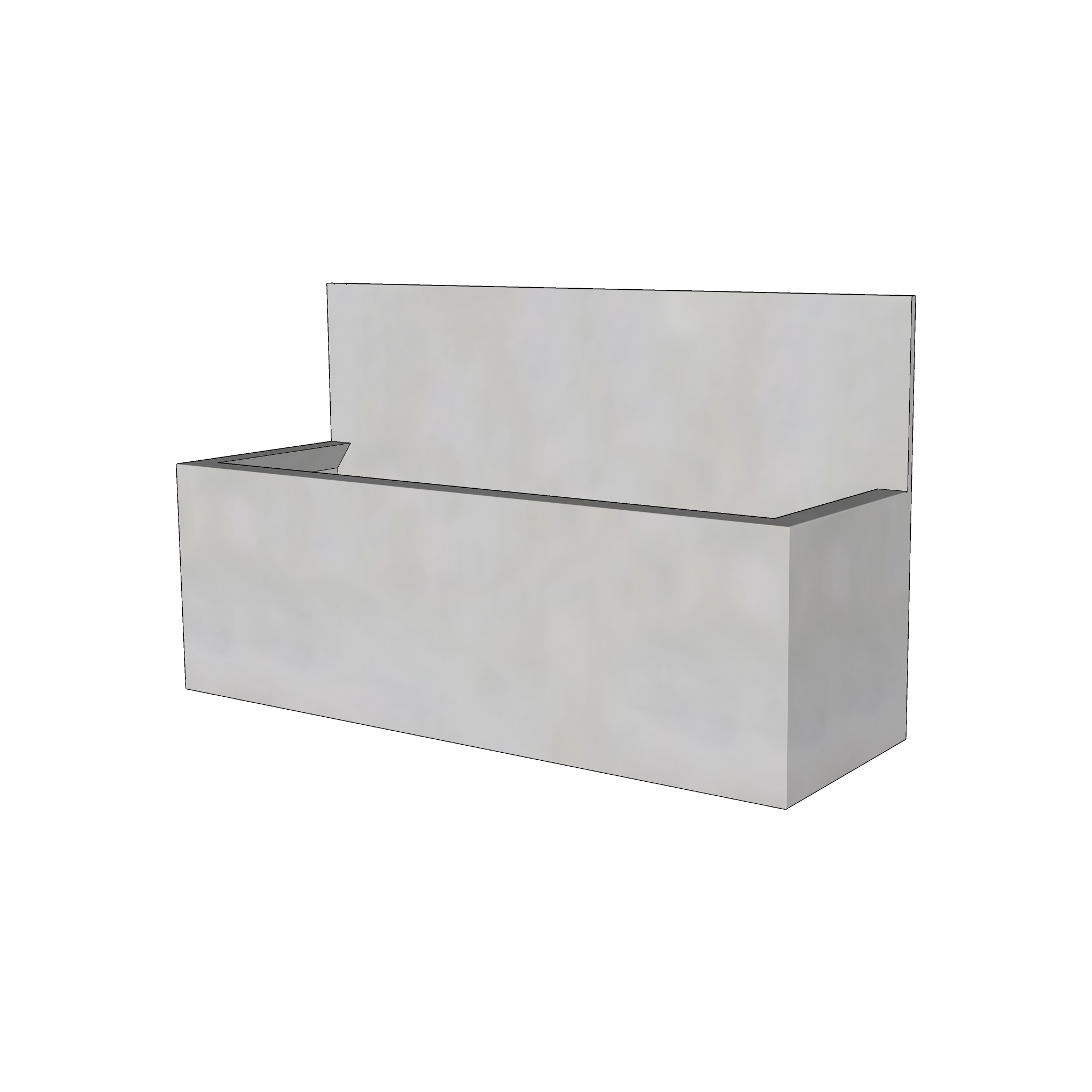

Modified Planter Walls

Lowering one or more of a planter’s walls can be useful if you want to abut several planters to provide the appearance of one continuous planter after they are planted. Planter walls can also be raised or lowered to provide barriers and building fascias.

Raised GRC Planter Walls | Satu Bumi

Facia Added to GRC Planter | Satu Bumi

Lowered GRC Planter Wall | Satu Bumi

GRC Planters Joined with Lowered Walls | Satu Bumi

Other GRC Planter Design Options

One of the great features of GRC is that it can be made to virtually any realistic shape or size. Therefore, it can be made to suit the design intent of most commercial landscaping projects. The following are examples of some of the designs and shapes that can be achieve with GRC.

GRC Rectangle Drip Trays | Satu Bumi

GRC Curved Edges | Satu Bumi

GRC H-Planters | Satu Bumi

GRC Planter with Integrated Drip Tray | Satu Bumi

GRC Cylinder with Recess Edges | Satu Bumi

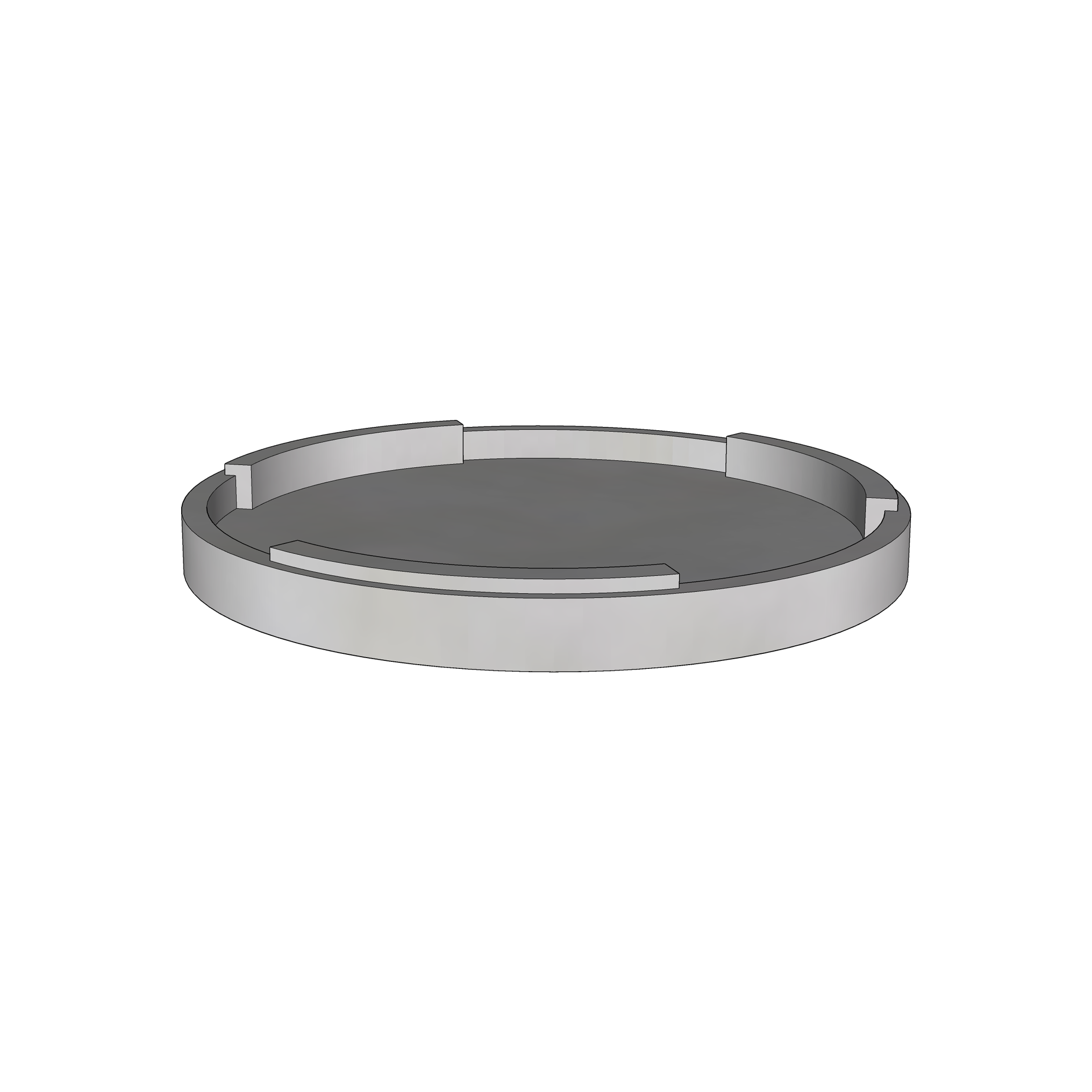

GRC Round Drip Tray | Satu Bumi

Round GRC Planter without Drip Tray | Satu Bumi

GRC Strengthening Baffles | Satu Bumi

GRC Corrugated Texture | Satu Bumi

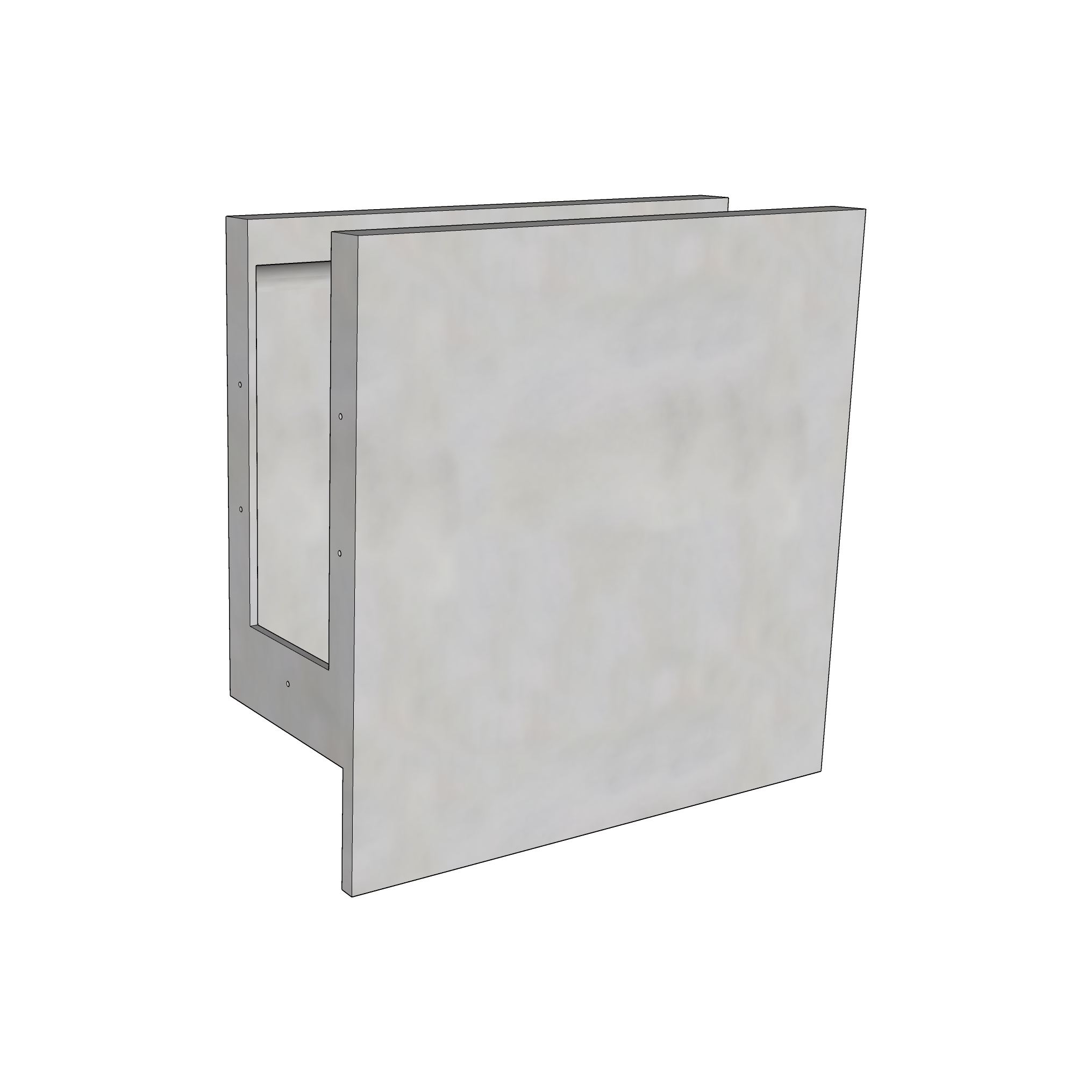

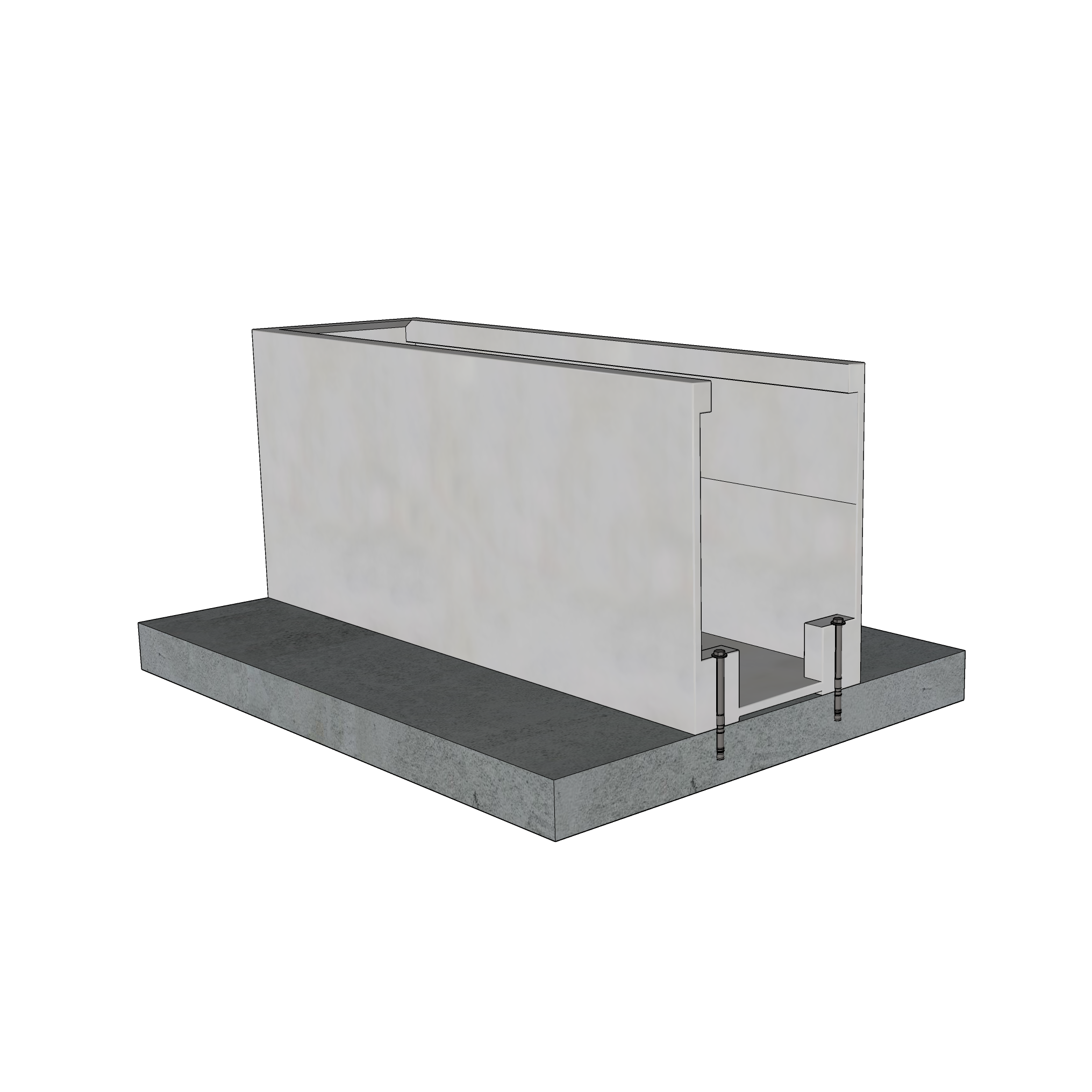

Moving & Fixing Options

GRC planters are much lighter than similar sized cast concrete planters because the walls of GRC planters are typically much thinner. However, large GRC planters can still be quite heavy. Therefore, when designing GRC planters, consideration should always be given to how they are going to be installed or moved around after installation.

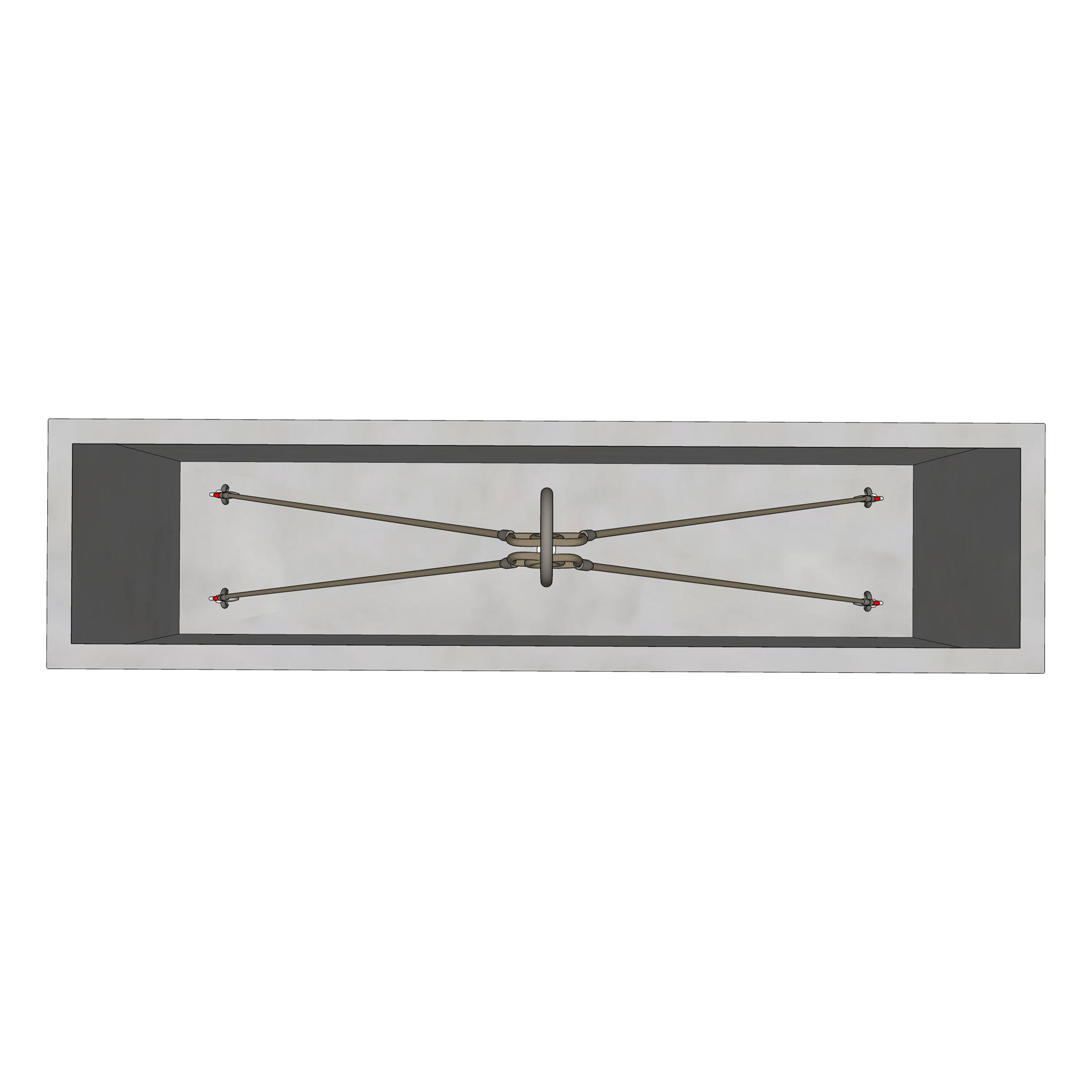

The Addition of Ferrules | Satu Bumi

Example Application of Ferrules | Satu Bumi

Slab Fixing Using Imbedded Ferrules | Satu Bumi

Lifting Lugs Section | Satu Bumi

Lifting Lugs Plan View | Satu Bumi

Embedded Side Ferruls | Satu Bumi

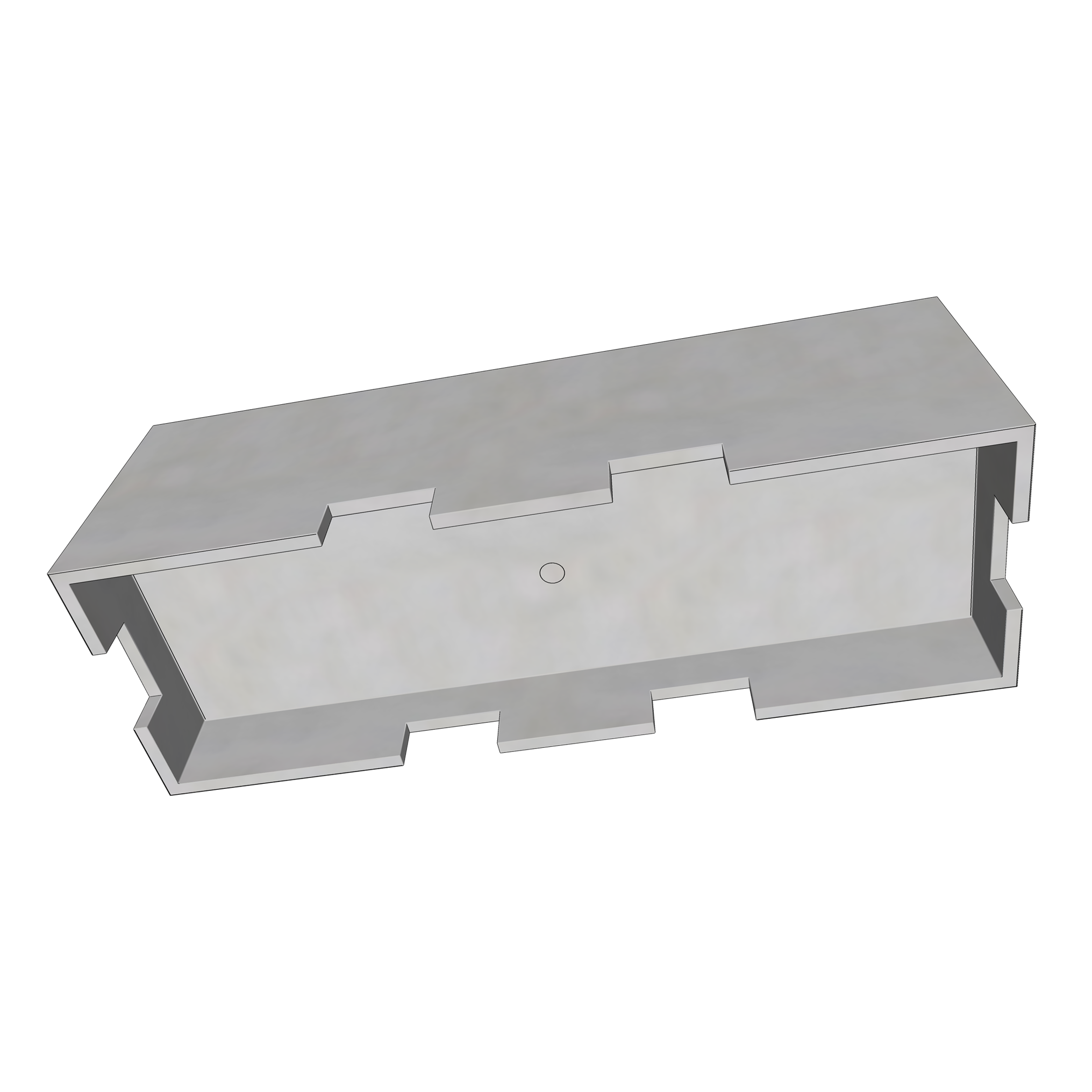

Forklift Access | Satu Bumi

Alternative Corner Designs for Square Edged Planters

The installation of multiple rectangle planters where corners are involved typically requires the use of L-Joint corners. However, both mitred and L-Shaped corner planter options are also available upon request and as shown below.

-

GRC Planters with Mitred Corner | Satu Bumi

-

GRC Planters with L-Shaped Corner | Satu Bumi

-

GRC Planters with L-Join Corner | Satu Bumi

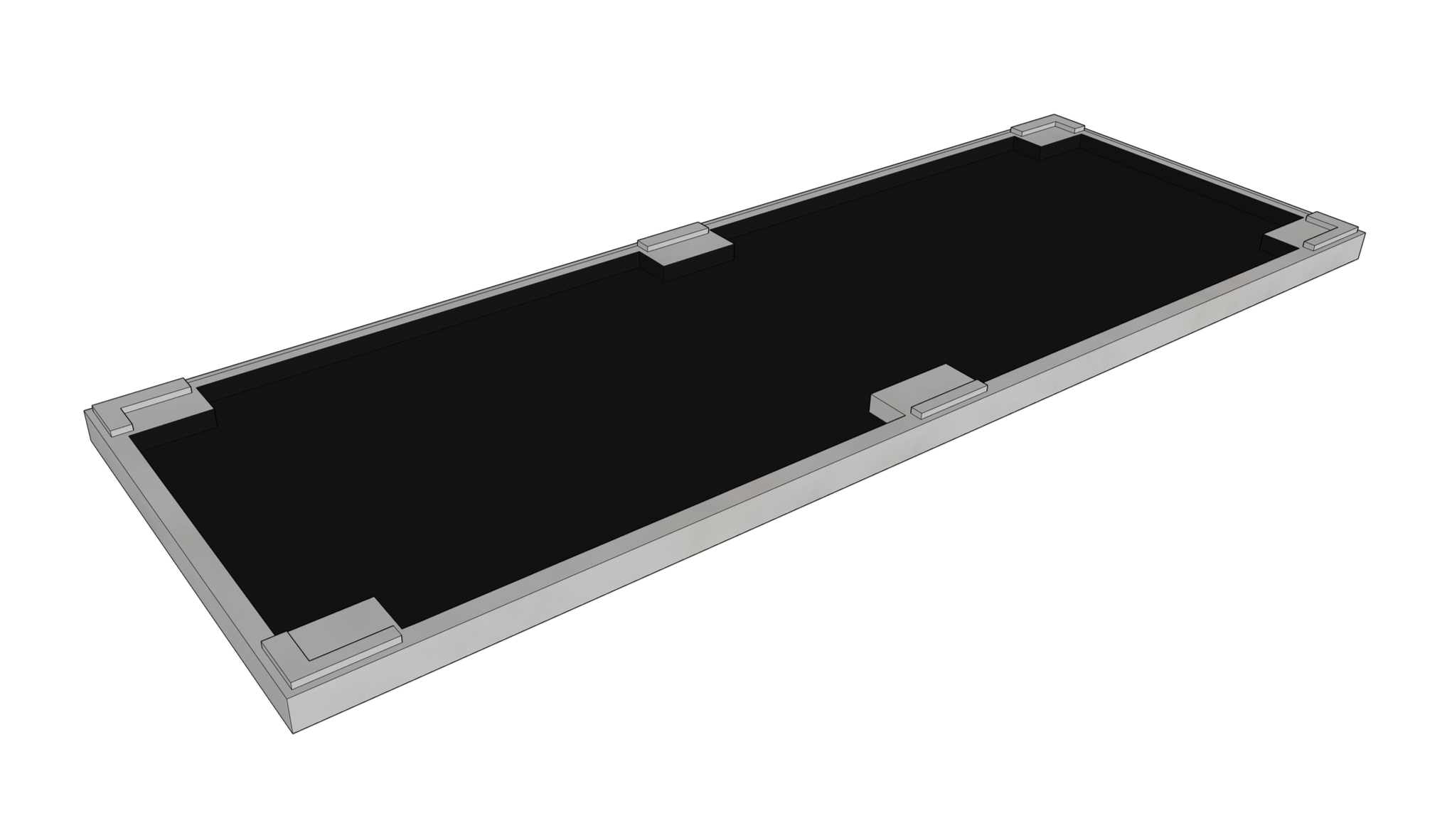

GRC Drainage Options

Appropriate planter drainage is essential for the maintenance of healthy plants by ensuring that water does not flood the planter.

Satu Bumi provides drainage cells for the bottom of all its GRC planters, at no additional cost, unless otherwise requested by the customer. These drainage cells consist of a crush resistant plastic drainage cell layer to facilitate efficient drainage covered by a layer of Geotech material to stop the contents of the planters from clogging the plastic drainage cell layer.

Depending the circumstances, the Satu Bumi supplied drainage cell may not be what is required. Therefore, Satu Bumi also offers the following options of a drainage riser, a raised drainage riser, and a pot planter holder to assist customers in designing the best drainage strategy for their projects.

Section of a GRC planter with a drainage cell included.

-

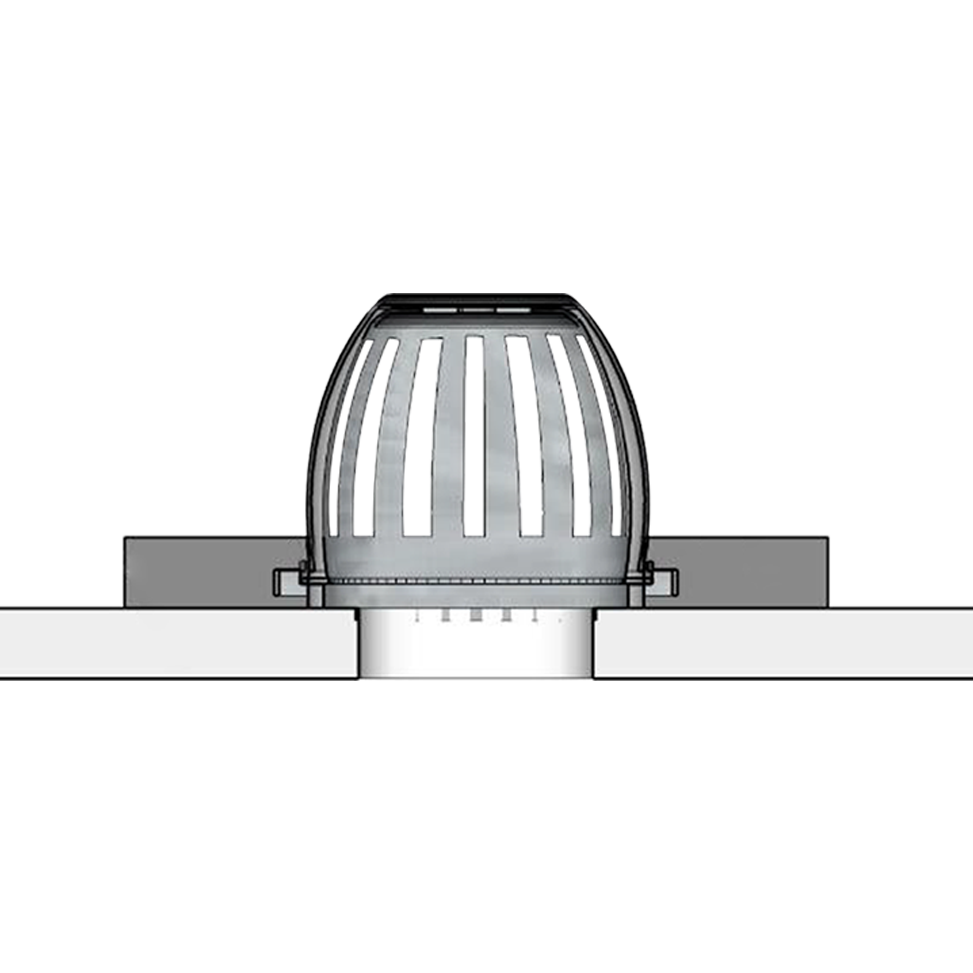

Drainage Riser for GRC Planter | Satu Bumi

These are used to prevent drainage holes on planters from blocking.

-

Raised Drainage Riser for GRC Planter | Satu Bumi

These are used to prevent drainage holes on planters from blocking and for retaining a predefined amount of water within the planters.

-

GRC Pot Planter Holder | Satu Bumi

These are primarily for indoor planters and are used to hold small plastic plant holders, within a larger GRC planter, that can be easily watered and replaced.

-

GRC Integrated drip trays | Satu Bumi

Used to hold excess water to avoid patio stains from over watering.

GRC Sealing Options

An essential element in the creation of a quality GRC planter, bench, table-top or water feature is the selection of the appropriate sealants. And there are hundreds of different sealants on the market that all have different features, benefits, quality and pricing. Therefore, Satu Bumi has invested considerable time and resources into selecting quality sealant options for the following purposes:

Nevertheless, any of the sealants can be changed at shop drawings stage if they do not suit the customer’s specific requirements.

-

Acrylic membrane sealants - these are used to “tank” the internal walls of planters to prevent leakage.

Bitumen sealants - are typically used to “tank” the internal walls of water feature ponds. However, bitumen sealants are also an option if you are looking for a higher level of internal sealant for GRC planters.

-

Penetrative sealants - these are used on the outside walls of planters to protect them against minor marking, moisture absorption and mold growth.

Anti graffiti sealants - these are heavy duty topical sealants used for GRC planters or street furniture located in public spaces.

-

These need to be of the highest quality, food safe, scratch resistant and stain resistant.

Edge Radius

Satu Bumi’s GRC planters and street furniture products all have an edge radius to remove sharp edges. An edge radius is both a safety issue and a chip prevention issue.

GRC Planter Edge Finish Example

Additional Download Information

Additional relevant downloadable information can be obtained through the Satu Bumi Download Library.